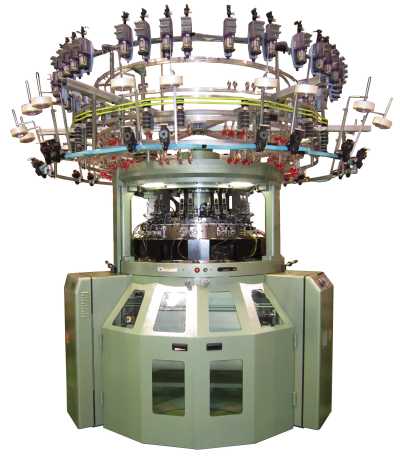

| Double knit garment-length electronic jacquard machine with both-side needle

selection |

|

・Double knit garment-length electronic jacquard machine with both-side

needle selection and transfer facility capable of knitting varieties of

unique fabrics. Equipped with auto-timing and auto-stitch mechanisms to

improve fabric quality.

・User-friendly F-type 6-colour stripers ensure stable striping. Elastomeric

yarn striping is also possible. |

| |

| 【Main functions and features】 |

| <3-position needle selection on both sides by SS actuators> |

・Our individual needle selection system using high performance SS actuators

ensures stable and reliable 3-position (K, T & W) needle selection

on both the cylinder and dial.

・Spring jack system is used for cylinder needle selection as our conventional

machines to ensure stable selection.

・Clip jack system is used for dial needle selection to ensure reliable

control of needles during loop formation. |

| |

| <Capable of producing varied garment length fabrics> |

・Links-links fabrics can be knitted by using both-side transfer.

・This model having the same number of cylinder transfer feeders and dial

transfer feeders enables both side transfer arbitrarily at every two courses.

This considerably reduces design limitations.

・Fabrics of higher stitch density can be knitted by using pointing transfer

cams designed base on transfer knitting theory. |

| |

| <F-type 6-colour auto-stripers> |

・Stable striping at high speeds thanks to various new mechanisms.

・Flip-up mechanism allows easy threading to the knitting head. The machine

can be operated with the stripers raised when knitting a non-striped fabric.

・Multi-finger operation (two or more fingers can feed yarns simultaneously)

is possible. |

| |

| <Auto stitch> |

・Auto stitch mechanism has been integrated onto both the dial and cylinder

or this model that selects those best suited needle timing and best suited

stitch amount for fabrics currently under production.

・thus, highly graded products can be offered. |

| |

| <Auto-timing> |

・The best suited timing is always selected automatically through cylinder

stitch cam slide mechanism, for instance, synchronized timing is selected

for jacquard and 2x1 rib stitches, and delayed timing is selected for 1x1

rib and many other structures.

・This new technology contributes to machine users for producing fabrics

with upgraded quality by employing always the best suited timing for respective

pattern area. |

| |

| <Garment length> |

| ・This model produces not only knitted yard goods but also garment length

as well witch facility value-added border ribs with separation yarn in

1 X 1 , 2 X 1 and tubular. |

| |

| <Blade type latch openers> |

・Blade type latch openers are installed at all feeders for reliable latch

opening.

・This type of latch opener prevents fancy yarns such as fluffy yarns and

slub yarns from being caught by the needles during knitting.

・Flip-up mechanism is employed to avoid damage to the needles. |

| |

| <Fukuhara Design System "FDS" (optional)> |

・ FDS is a knit design system for making patterns for our electronic jacquard

machines.

・Compatible with Windows 2000/XP/Vista/7 operating systems and peripheral

devices such as printer, scanner, etc.

・Complicated pattern data for both-side structures and garment lengths

can be made easily by FDS. For garment lengths, various data such as pattern

data for cuff and body, separation thread, auto-timing, auto-stitch and

stripers are automatically created based on the basic pattern information.

Such data are stored in a USB flash memory stick. |

| |

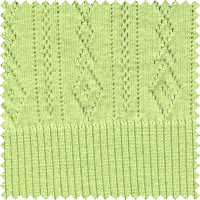

| Fabric Samples |

STRUCTURE PATTERN / 2X1 RIB CUFF |

LINKS / 2X1 RIB CUFF |

RIB MESH TRANSFER / 2X1 STRETCH CUFF |

MOCK LINKS / 2X1 RIB CUFF |